|

| January 27, 2015 | Volume 11 Issue 04 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

What's the difference between 17-4PH and 316L stainless steel for pressure sensors?

By Greg Montose and Karmjit Sidhu, American Sensor Technologies

Stainless steel pressure sensors and transducers are most commonly manufactured from either 316L or 17-4 PH. Both materials are relatively inexpensive and easy to machine in comparison to high-strength nickel alloys. They offer good material strength and good elasticity, which allows for movement of a diaphragm. There are differences in their material properties that relate to both industrial and hazardous location applications that drive a preference for each material.

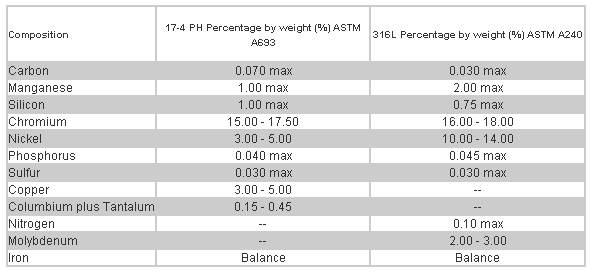

While different variations of these materials exist, AST has chosen the most basic and common forms used in the sensor marketplace today for comparison. The difference in iron content contributes to the magnetism and corrosion resistance. 17-4 PH stainless steel is magnetic and less corrosion resistant than 316L stainless steel. Standard 316L is slightly magnetic, but non-magnetic versions are available.

Material strength

While the general understanding that stainless steel has a high material strength is true when comparing it to a material such as plastic, the differences between types of stainless steel can be significant. When comparing 17-4 PH to 316L, 17-4 PH has a higher material strength. For many hydraulic pressure systems, where pressure surges and high cycles are common, 17-4 is more frequently used because it is a good spring material. Pressure sensors and transducers can be specified with proof (typically two times the rated pressure) and burst (typically five times the rated pressure) ratings that are equal between the materials; yet there is a greater chance that 17-4 PH will measure accurately for a longer period of time when higher pressures and pressure transients above the rated pressure are present.

Liquid and gas compatibility

Stainless steel is stainless steel, right? When measuring liquids and gases, the type of pressure sensor material will be critical. 17-4 PH is used in various non-corrosive or mildly corrosive liquids and gases. Hydraulic fluid, brake fluid, fuels, and other standard industrial liquids will work well with 17-4 PH stainless steel. With higher nickel content, 316L stainless steel will work for these fluids in addition to many liquids and gases with more corrosive properties. For example, natural gas with low H2S content will need 316L to survive corrosion. Water (excluding salt water) is often considered a non-corrosive liquid, although 316L is preferred for pressure measurement. Various pH levels can cause the 17-4 PH material to generate mineral deposits and clog process connections. Gases, such as hydrogen, require 316L material. Hydrogen ions are small enough to penetrate the grain structure of 17-4 PH stainless steel, thus breaking down the diaphragm over time as a result of embrittlement.

For ultra-high-purity applications such as semiconductor process equipment, 316L VAR (Vacuum Arc Melting) material is introduced to reduce non-metallic impurities. The material surface finish is also put through a process called electro-polishing. This further reduces impurities from coming in contact with the liquid or gas by removing non-metallic imperfections, as well as a small amount of the metallic surface.

NACE MR0175/ISO15156

NACE MR0175/ISO15156 recommends materials for oil and gas equipment in production and treatment applications. Currently, 17-4 PH stainless steel is not an accepted material. While its strength is high, the corrosion resistance factor for oil and gas, where liquids and gases can have corrosive media such as hydrogen sulfide, prohibits the materials usage for pressure transducers. 316L is a listed and accepted material. Similarly, ABSA (Alberta Boiler Safety Association) currently does not accept 17-4 PH material under code ASME B31.3 for instrumentation and fittings, while 316L stainless steel is approved with certain restrictions. Boiler and process installations require the sensor documentation be registered and approved with a CRN (Canadian Registration Numbers) code.

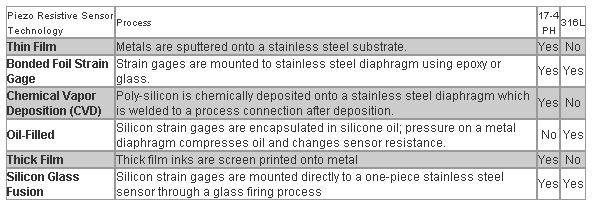

Sensor technology

The technology used is an important factor. Certain technologies are limited in the material to which they can be applied. The strain gages applied to the diaphragm should match the thermal properties of the material to which it is applied. 17-4 PH stainless steel has a mean coefficient of thermal expansion of 6.0 x 10-6 in./in./F with H900 heat treatment, whereas 316L ranges from approximately 9 to 11 x 10-6 in./in./F. Technology such as thin film is limited to 17-4 PH, because the temperature of the sputtering process is too high at the diaphragm.

In summary, the difference in sensor material and technology can play a critical role in pressure transducer selection. Be prepared with information regarding the liquid or gas being measured and its application to help find the better option between materials. If neither 17-4 or 316L suffice, special alloys can be offered.

For more information, go to www.astsensors.com or email info@astsensors.com.

Published January 2015

Rate this article

View our terms of use and privacy policy